IGNITION

SYSTEMS

> TRANSISTOR IGNITION

MODULES > HOW TO BUILD

HOW TO BUILD TRANSISTOR IGNITION MODULES

"Most carburetor problems are electrical" That was

told to me by a savvy old auto mechanic long ago and it has proven true

more times than I can remember.

The standard Kettering points/condenser ignition timing setup works

just fine if the point faces are parallel and clean, are closed with

proper pressure, and the condenser (capacitor is the current term) is

good and of the correct value. A lot of ifs, don't you think? Also,

unfortunately for us model engine builders, either a grossly oversize

points/condenser set from older style lawn mower engines must be used

or a miniature points set will have to be fabricated from questionable

materials and with questionable accuracy. Most model engines don't have

shaft oil seals and just a little oil leakage onto the points will

cause major problems. Ever wonder why so many model gas engines on

display at shows are never ran? Do you suppose it's because they are

easy starters and good runners? Some may be. But how many really

otherwise great engines won't run or are so hard to start because of

ignition problems, that the owner won't even bother? What a shame! If

you don't like having your engines ending up as just shelf models, then

keep reading!

I came across the answer some years ago in a magazine article written

by Floyd Carter and all my spark plug ignition model gas engines use it

with great results. The original Transistor Ignition Module (TIM - 4)

is a simple two transistor circuit that can easily be home built. TIM-4

was designed to operate on 3.6 volts (three Ni-Cad cells in series) for

use with model airplane engines. It eliminates all the problems of

standard points systems. The coil will give a good hot spark every

time. The circuit requires very little current to trigger (25 ma). This

allows use of a tiny micro switch for the points which can be easily

hidden. There is no arcing, so the contacts in the micro switch will

never burn. If you want your model antique engine to be authentic, or

on already built engines which you don't want to change, the old point

set can be used if desired. A "condenser" is not needed but can be

included for looks.

And now for the really BIG advantage........ Since we now have a

circuit that is so easy to trigger, we can use a tiny magnetic sensor

instead of mechanical point contacts (high amperage switch)! The

magnetic sensor is called a "Hall Effect Device". They are really tiny,

measuring just .125" x .170" x .060" thick (3mm x 4.3mm x 1.52mm).

Instead of a cam to operate contacts, a tiny magnet (only 1/8" diameter

by 1/16" thick - or smaller) mounted on a drum or disk (cam gear)

triggers the Hall device which is mounted in close proximity. The Hall

sensor is located remote from the circuit board which can be hidden

under the engine, or wherever you wish. Now you have the ultimate in

small and reliable ignition, no mechanical parts, rub blocks or contact

points at all! The circuits are extremely reliable.

Floyd is a retired aerospace electronics expert now enjoying life and

intends to continue doing so. He sells his TIM-4 units ready made. He

does not make any of the units available as kits. There is actually

nothing at all difficult in building these circuits except a little

care and the exercise of some common sense. With some help and advice

from Floyd (and against some!) I am making these kits available under

the following conditions: If you are not proficient at soldering, don't

have a 25 to 35 watt (max.) soldering pencil (no 150 - 300 watt solder

guns), don't have some previous experience with electronic parts and

circuit boards, then you probably shouldn't order these kits because I

positively will not replace any damaged part at my expense for any

reason. I will sell replacements for damaged parts at very reasonable

prices in the unlikely event that you should need them.

I changed some of the components of the original TIM unit for 6 volt

operation on stationary engines. I designate this as the TIM-6.

To run an engine with electronic ignition you will need: TIM-6 module,

a suitable 6 volt ignition coil (see below), spark plug and a good 6

volt battery that can supply at least 5 amps.

These ignition modules may be used on multi cylinder engines if model

ignition coils such as the Exciter, Modelectric or Gettig and having a

primary winding resistance of not less than 1 ohm. This combination

runs my V-Twin, V-Four and other engines with no problems at all.

If you want to use automobile or motorcycle ignition coils with a

primary winding resistance less than 1 ohm, use a proper ballast

resistor in series with the coil so the current draw is not over 4.5

amps.

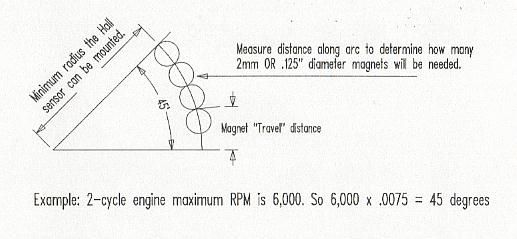

Ignition Dwell Angle

A rule of thumb to calculate

dwell angle is Cam Shaft RPM x .0075 for 4 cycle engines, or Crankshaft

RPM x .0075 for 2 cycle engines. This will determine the shaft rotation

in degrees that the coil should be energized (points closed or Hall

Sensor turned "ON"). Too little dwell angle will limit top engine RPM

as the spark will be weak or non existent - too much dwell angle will

overheat the coil and electronics at low RPM. A simple calculation or

two will determine the radius from the center of the shaft to mount the

magnet and Hall Sensor. High speed engines need small radius (or

several magnets in an arc) to get enough dwell angle, slow running

engines require greater radius (or a smaller magnet) to prevent

excessive dwell angle. Calculate the dwell angle for the highest

expected engine RPM. Therefore, if a 2-cycle engine has a top RPM of

say 6,000 RPM, then .0075 times 6,000 = 45 degree dwell angle. In the

above case, draw a circle representing the smallest radius you can

mount magnets in a disk and also have a Hall sensor mounted at the same

radius. Engine features will determine this. Draw the 45 degree angle

lines from the center of that circle. The arc on the circle between the

45 degree lines is the length of arc you need to have magnets. For a

4-cycle engine at 6,000 RPM, use the cam shaft speed of 3,000 RPM which

gives a 22.5 degree dwell angle. If the Hall sensor can be mounted so

that it can be rotated around the center of the shaft, ignition timing

can be adjusted for "advance" or "retard". Try to get the dwell right

for a nice running engine. See the diagram below.

Very few model engines will need more than one magnet to obtain correct

dwell angle - none of my engines needed more than one magnet/cylinder.

The following measurements are for the Hall sensors and magnets that I

currently have available.

TIM-6 magnets are 1/8" dia. by 1/16" thick. With the 1/8" dia. rare

earth magnets at .030" away from the Hall Sensor face, the sensor will

be turned "ON" during the time it takes for the magnet to move .125"

across the sensor face. In other words at a certain point, as one edge

of the magnet starts to move cross the Hall sensor face, the sensor

will turn "ON" and stay "ON" until the 1/8" diameter magnet has moved

across the Hall Sensor face for a distance of .125". As the magnet

moves beyond that point, the Hall sensor will turn "OFF" again. The

distance the magnets move during turn "ON" does not change

significantly with the magnets from .025" to .035" from the Hall

Sensor, so distance away is not that critical.

For the 2mm diameter magnet at a distance of .030" away from the Hall

Sensor face, the Hall Sensor will be turned "ON" during the time it

takes for the 2mm dia. rare earth magnet to move a distance of .050"

across the face of the sensor. All these measurements were made using

the DRO on my milling machine.

More info is in Strictly I.C. magazine #27 and #36. Back issues

available robert@strictlyic.com

Please Note

I get asked a lot of questions

about using these ignition modules on chain saw, weed eater and other

non-stationary and/or non-model engines. Many of these types of engines

have been converted and are operating in various applications. However,

I make no claim of suitability of any of the above ignition units for

non-model engines. Some of these engine types may be suitable and some

may not be. If you want to convert these engines, you are on your own,

so you should consider the use of these ignition modules and/or coils

on non-model engines to be experimentation on your part. Please also

note - electrical items are not returnable for refund for obvious

reasons.

With the above understanding,

you want to go ahead anyway, here are some guidelines. With the right

battery voltage and - very important - an ignition coil with a primary

resistance of not less than 1 ohm, I see no reason why an enterprising

person shouldn't be able to convert most, if not all, of these engines.

In a nutshell, determine from your engine the minimum circle diameter

you can use to get the proper dwell angle (see above) from the rotating

magnet(s) which are mounted on a drum or disk somewhere on the

crankshaft (2 cycle) or cam shaft (4-cycle) and suitable mounting of

the stationary Hall Sensor in close proximity to the rotating magnet(s)

and make that installation. That is all the modification you need to do

to a single cylinder engine. There are many ways to set up

multi-cylinder engine ignition systems. Usually multiple magnets and a

distributor are required. Again, I don't do consulting so you are on

your own. Also, if you intend to use the engine with radio control,

remember that the entire ignition system - TIM module, coil, plug wire,

plug, etc. should be shielded and grounded to the engine to prevent

radio interference and possible loss of control of your model. On the

other hand, I have talked to some fellows who say they have not found

this necessary with their particular radio by installing the radio as

far aft in the plane fuselage as possible.

You decide what you are comfortable with.

Good luck!

|